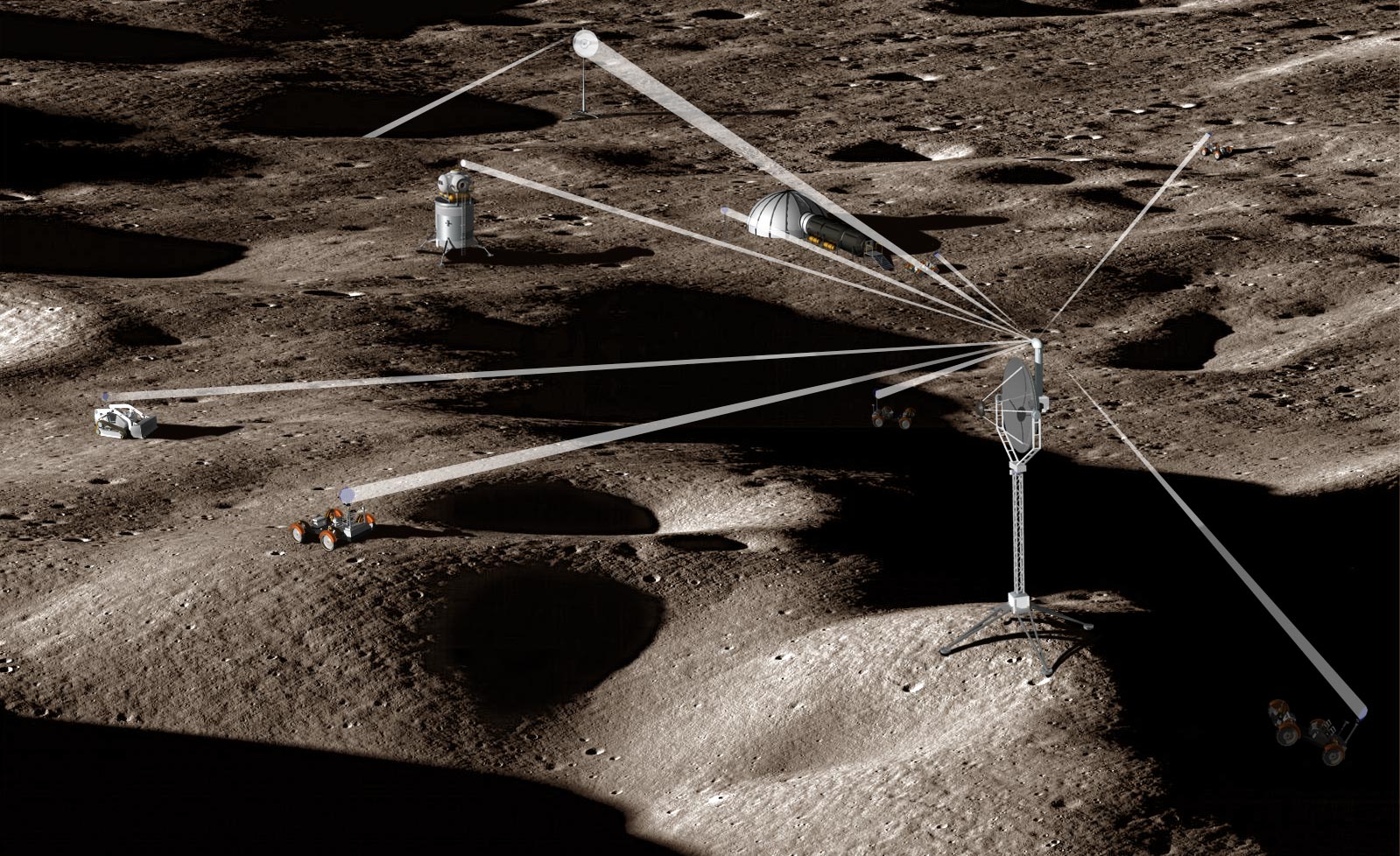

Light Bender Artist Concept. Light Bender is a novel concept for the generation and distribution of power on the lunar surface within the context of the Artemis mission and the “Long-Term Human Lunar Surface Presence” that will follow. The innovative concept is based on a heliostat that utilizes Cassegrain telescope optics as the primary means to capture, concentrate and focus the sun’s light. Credit: Ronald Neale

NASA’s Volatiles Investigating Polar Exploration Rover, or VIPER, conducts mobility testing at NASA Glenn’s Simulated Lunar Operation Laboratory (SLOPE). Credit: Bridget Caswell/Alcyon Technical Services, LLC, NASA

The selected proposals, grouped by company, and the respective partnering NASA centers are:

Aerojet Rocketdyne in El Segundo, California (two selections)

- Fully Additively Manufactured LOX-LH2 Engine Demonstration – NASA Marshall

- Electrically Actuated Quick-Disconnect Coupling for Cislunar and Lunar Surface Cryogenic Propellant Transfer – NASA Marshall

Blue Origin in Kent, Washington (two selections)

- Friction Stir Additive Manufacturing – NASA Langley and NASA Marshall

- Metallic Thermal Protection System – NASA Ames and NASA Langley

The Boeing Company in Arlington, Virginia

- Complex Curvature Retractable Pin Tool Friction Stir Welding Pathfinder Campaign – NASA Marshall

Canopy Aerospace in Denver

- Low-Cost Reusable Thermal Protection System Substrates as an Alternative to Alumina Enhanced Thermal Barrier – NASA Ames

Lockheed Martin Corporation in Bethesda, Maryland (three selections)

- Friction Stir Welded Blanks for Advanced Formed Shapes – NASA Langley

- In-Space Manufacturing Technologies for Thermoplastic Composites – NASA Glenn, NASA Goddard, NASA Langley, and NASA Marshall

- Oscillating Heat Pipe Technology for Aero Entry and Commercial Applications – NASA Ames and NASA Marshall

Maxar in Westminster, Colorado

- Automated Robotic Assembly of the Light Bender System – NASA Langley

Phase Four in El Segundo, California

- Development of an ASCENT (Advanced Spacecraft Energetic Non-Toxic) Gas Feed System for the Phase Four RF (Radio Frequency) Thruster – NASA Marshall

Psionic, LLC in Hampton, Virginia

- Commercial Wind Measurement Constellation – NASA Langley

Roccor, LLC (Redwire) in Erie, Colorado

- Characterization of High Aspect Ratio Booms for Large Apertures – NASA Langley

Sierra Space in Louisville, Colorado

- Development of Low-Cost High Temperature Reusable Thermal Protection System – NASA Ames and NASA Johnson

Stratolaunch in Mojave, California

- Bringing Shuttle Orbiter TPS into the 21st Century – NASA Ames

Venturi Astrolab in Hawthorne, California

- Demonstrating Lunar Tire Technology Readiness – NASA Glenn and NASA Johnson

Since the inaugural ACO in 2015, STMD has supported more than 75 ACO projects, including the new awards. The period of performance will be negotiated for each agreement, with an expected duration of between 12 and 24 months. The total estimated value of agency resources to support the agreements is approximately $14.5 million.

The selected proposals will be led by a diverse array of companies including small and large businesses and will develop a broad range of technologies.

Venturi Astrolab will work with NASA’s Glenn Research Center in Cleveland and Johnson Space Center in Houston to demonstrate a durable lunar rover tire that can tolerate extremely cold temperatures. The design could allow mission planners to consider more lunar locations for rover exploration and longer traverses.

Psionic seeks to expand a well-tested landing technology called Navigation Doppler Lidar to make wind measurements. The small business will work with NASA’s Langley Research Center in Hampton, Virginia, to adapt the technology for new potential applications such as real-time air traffic management using a satellite constellation and providing better data for studying the climates of both Earth and Mars.

Lockheed Martin will advance in-space manufacturing technologies for thermoplastic composites. This low-cost material requires less energy to make in-orbit compared to metal. The company will test the technique in simulated space environments with several NASA centers.

“The collaborations reduce the development cost of space technologies and aim to accelerate the infusion of new capabilities,” said LK Kubendran, STMD, ACO, and Tipping Point lead. “The 2022 ACO solicitation topics were intentionally broad, allowing industry to propose emerging capabilities with the widest potential benefit, increasing access to space for all.”