Optical micro and nanofibers (MNFs) have extensive applications in nonlinearity generation, near-field optics, quantum optics, and miniaturized sensing. Although MNFs have fostered the development of various disciplines, there have been few studies on the topic until the convenient fabrication of low-loss MNFs was made possible.

In the standard and most conventional methods of drawing out silica nanowires, the fiber material would be first softened by local heating and then thinned and elongated by applying a pulling force. The decreased diameter of fabricated MNFs can approach the subwavelength dimension. It would thus support modal fields with strong evanescent waves tunneling through the silica material into the surrounding medium. Easy fabrication, low loss, light mass, and pronounced evanescent waves have made MNFs one of the best candidates for studying light-matter interactions.

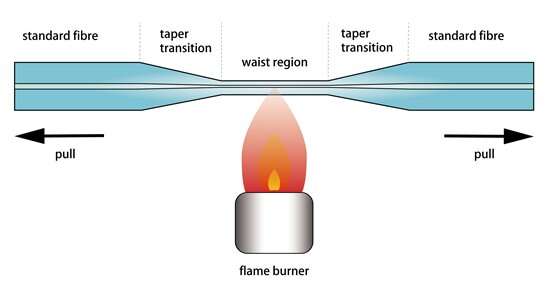

Many efforts have been devoted to improving the fabrication units to produce MNFs of desired quality. The most common taper-drawing machine contains a flame and two translation stages. They apply the pulling force to the fiber by stretching its fixed ends in opposite directions. According to the hot-zone theory, the specific shape of MNFs is determined by the length variation of the heated region relative to the net elongation of the fiber.

MNFs with designed taper geometries can be prepared by adopting the “flame brush” technique to manipulate the hot zone. However, using flames to heat the fiber suffers from air fluctuations and the inertia of the moving burner. Electrical heaters were introduced for programmable and steady temperature distribution.

Alternatively, CO2 lasers can be turbulence-free heat sources that generate heat through material absorption. Their function requires complex optical alignment and high input light power. The substitution of translation stages can take multiple forms as long as the pulling force can be exerted along the fiber. Although the techniques in principle provide a myriad of viable fabrication configurations, each specified for certain operational conditions, they are explored only within the most explicit scheme of “heat and pull”.

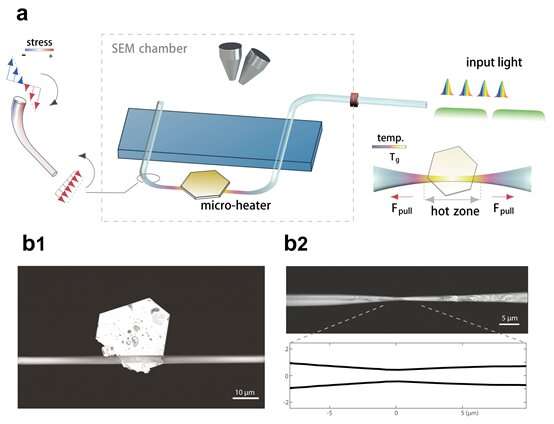

In a new paper published in Light: Advanced Manufacturing, the first author Qiannan Jia and co-workers have developed a unique fiber-tapering technique that combines plasmonic heaters and deformed optical fibers.

The researchers demonstrated a unique technique for MNF fabrication that excluded using any of the aforementioned bulky fabrication components. Pieces of metal plates were introduced to serve as portable micro-sized heaters, which absorbed fiber-delivered light efficiently through plasmonic effects. The light power required in this step was only a few microwatts. The tensile stress of the macroscopically bent fibers provided the pulling force without the use of translation stages.

The researchers emphasized that the proposed plate-fiber system was self-sufficient in heat and pull. Implementing the process required no conventional bulky accessories, such as the translation stage, flame burner, or free-space optical components. Owing to its small volume, the plate–fiber system could be transferred into a scanning electron microscope (SEM) chamber. The dynamic tapering process was visualized with nanometer precision for the first time.

More information:

Qiannan Jia et al, Fibre tapering using plasmonic microheaters and deformation-induced pull, Light: Advanced Manufacturing (2023). DOI: 10.37188/lam.2023.005

Citation:

A fiber-tapering technique that combines plasmonic heaters and deformed optical fibers (2023, April 12)

retrieved 15 April 2023

from https://phys.org/news/2023-04-fiber-tapering-technique-combines-plasmonic-heaters.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.